Forging

Forging is a popular manufacturing technique for metals. We provide custom forgings for aerospace, automotive, hydraulics, oil, gas, marine,power generation and defense industries.Tolerance is +/- 0.01 mm. Materials include aluminum, brass, bronze, copper, Invar, iron, magnesium, steel, titanium, ferrous and non-ferrous metals are available.

Open Die Forging

Open-die forging is also known as smith forging. In open-die forging, a hammer strikes and deforms the work piece, which is placed on a stationary anvil.Metal parts are worked above their re-crystallization temperatures-ranging from 1900°F to 2400°F for steel and gradually shaped into desired configuration through the skillful hammering or pressing of the work piece.

Production Capability

•Materials: Carbon steel, Stainless steel, Alloy steel, Aluminum alloy, Copper alloy, etc

•Weight range: ≤50Ton

•Output per year: 50000 Ton

Surface Finish Option

Rust proofing,Painting,Galvanizing,Power coating

Typical Products

•Large dimension

•Simple geometry

•Bars

•Blocks

•Rings

•Hollows

•Spindles

•Shafts

Close Die Forging

Closed die forging also called Impression Die Forging,presses metal between 2 dies that contain a precut profile of the desired part.

Production Capability

•Materials: Carbon steel, Stainless steel, Alloy steel, Aluminum alloy, Copper alloy, etc.

•Weight range: 0.2 kgs-50 kgs

•Output per year: 3000Ton

•Surface Finish Option: Rust proofing, Painting,Galvanizing, Power coating

Typical Products

•Spanners

•Pedal

•Cranks

•Gear

•Blanks

•Valve Bodies

•Hand Tools

•Crankshafts

•Coins

Press Forging

Press forging works by slowly applying a continuous pressure or force.The amount of time the dies are in contact with the work piece is measured in seconds. The press forging operation can be done either cold or hot.

Press forging can be used to perform all types of forging, including open-die and impression-die forging. Impression-die press forging usually requires less draft than drop forging and has better dimensional accuracy. Also, press forgings can often be done in one closing of the dies, allowing for easy automation.

Upset Forging

Upset forging increases the diameter of the work piece by compressing its length. Based on number of pieces produced, this is the most widely used forging process. A few examples of common parts produced using the upset forging process are engine valves, couplings, bolts, screws, and other fasteners.

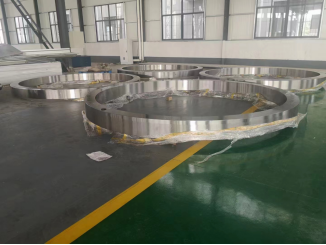

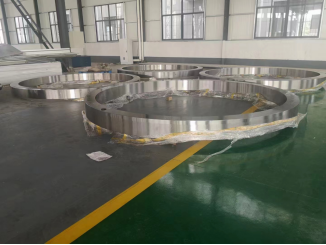

Roll Forging

Roll Forging(Ring forging) is a processing method that plastically deforms the billet or ingot under the action of ring equipment and tools (die) to obtain a forging of a certain ring size.The advantage of this process is there is no flash and it imparts a favorable grain structure into the work piece.

Production Capability

•Materials:Stainless Steel 300 and 400 series, Aluminum alloy,Grade, Monel etc.

•Range: φ≤2000mm, Weight≤20 tons

•Output per year:1-1000k pieces

Typical Products

•Axles

•Tapered levers

•Leaf springs

•Connecting rods

•Twist drills

•Wrenches

•Spikes

•Hoes

•Picks

•Turbine Blades

Precision Forging/Net-Shape And Near-Net-Shape Forging

Precision forging is an innovative manufacturing process for the flashless,near-net shape production of high-performance components. Outstanding material characteristics as well as a reduced process chain and a high material efficiency are the essential advantages of precision forging.The final product from a precision forging needs little or no final machining. Precision forging also requires less of a draft, 1° to 0°. The disadvantage of this process is its cost, therefore it is only implemented if significant cost reduction can be achieved.

sales@incrementstech.com call us:+86 197 1029 9116

sales@incrementstech.com call us:+86 197 1029 9116

sales@incrementstech.com call us:+86 197 1029 9116

sales@incrementstech.com call us:+86 197 1029 9116

Wechat number:WEIXINHAOMA

Wechat number:WEIXINHAOMA